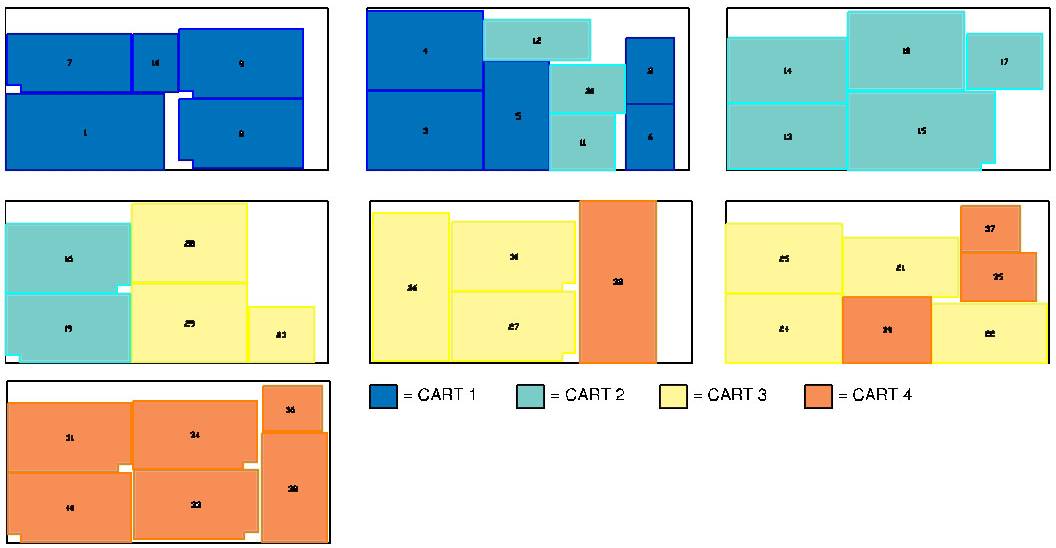

Do you unload your parts onto carts after they are machined? How many carts can you park near the router? With Cart Control Nesting, you can set the number of carts and the resulting nests will never exceed the available carts. This help you manage off loaded parts at the machine while balancing the maximum material yield by mixing parts from several jobs using the same material.

Have a large project with multiple jobs and you still want to keep your production flowing? With Cart Control Nesting you can now prioritize your jobs’ parts and send them to production as they are completed without waiting for the entire project to be completed. Take 5 jobs and prioritize their parts in order to make sure that parts from Job 1 and 2 are completely machined before moving on to the others. This keeps the production flow of your shop moving by sending completed jobs to the shop floor while the remainder of the jobs’ parts are finished. You define how you want your cart to be prioritized and what the material yield minimum is for each material.

Established in 1986, the founders of CIM-TECH realized that a CNC machine was only as good as your ability to program it. Computer Integrated Manufacturing (CIM) was needed to bridge the gap between Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM). CIM provides for a seamless solution with a common interface for design and manufacturing. From this basic concept a new company was created, CIM-TECH.

Read more7512 Dr. Phillips Boulevard Suite 50-859, Orlando, FL 32819

Telephone: 877-549-8211

E-mail: info@cim-tech.com