Shaped by years of experience in custom, industry-specific programming, CIM-TECH offers a deeper, more robust software solution. Router-CIM Automation Suite offers a familiar Windows-style interface, and its enhanced capability supports a variety of third party software to control other equipment.

Router-CIM 2021 Automation Suite is a complete CNC machine programming package. This versatile product combines Computer Aided Manufacturing (CAM) features with the power of AutoCAD, the world’s premiere Computer Aided Design (CAD) software. Router-CIM 2021 is compatible with AutoCAD 2021, 2020 and 2019. Includes 64 bit support.

Now one complete package can take you from concept drawing to machine-ready code automatically!

Router-CIM’s Computer Integrated Manufacturing Means:

• Tool paths are created and saved inside AutoCAD

• You can use all of AutoCAD’s commands on the tool paths

• No need to DXF out or save drawings to an older version of AutoCAD

• All tool paths are stored on separate layers so the DWG contains both design and manufacturing data

• One system to learn and use; combined design and manufacturing makes for a reduced learning curve

• 80% of CAM commands are CAD related commands

• Router-CIM uses unified design and manufacturing command set

• A single database for design and manufacturing simplifies file structure and edits

• Better designs because drawings are “fixed” for manufacturing

• Your design standards can be integrated into manufacturing standards

• Router-CIM data is stored in the industry standard DWG file format

• Seamless integration within AutoCAD includes an updated ribbon style toolbar

• Improved materials database functionality allowing for easy export/import, material reports and material editing characteristics

• Advanced Scrap Management giving you the option to select scrap variables in a multitude of ways

• Router-CIM post processors are available for virtually all machine controllers. We support the most complex machinery

• Powerful advanced nesting features that are only available in Router-CIM

• Custom written software is available and can reduce the number of steps between design and manufacturing

• Parametric macros are included, and you do not need to be a VB programmer to write them. Over 40 MDF door macros and 20 millwork macros are included!

• Multiple data sources and types: DWG, DXF, macros, 3D solids, surfaces, ellipses, splines, text and more

You can cut Solid models right inside AutoCAD. We include an Inventor link that transfers a model, assembly, or drawing view directly into Router-CIM. Router-CIM will pick up the cutting depth directly from the Solid model.

Material Yield Reports: Customizable material yield report is automatically saved as an Excel Spreadsheet for you. Analyze your yields and compare the savings you get with Router-CIM.

Tool and Cut Time Study: Customizable tool life and time study spreadsheet included! Analyze your tool life and get accurate time studies using Router-CIM. Our tool life and time study spreadsheet computes the acceleration / deceleration curve to provide accurate cutting times. Using this tool, you can figure your job costs and labor hours required. Best of all, the spreadsheet is customizable by the user!

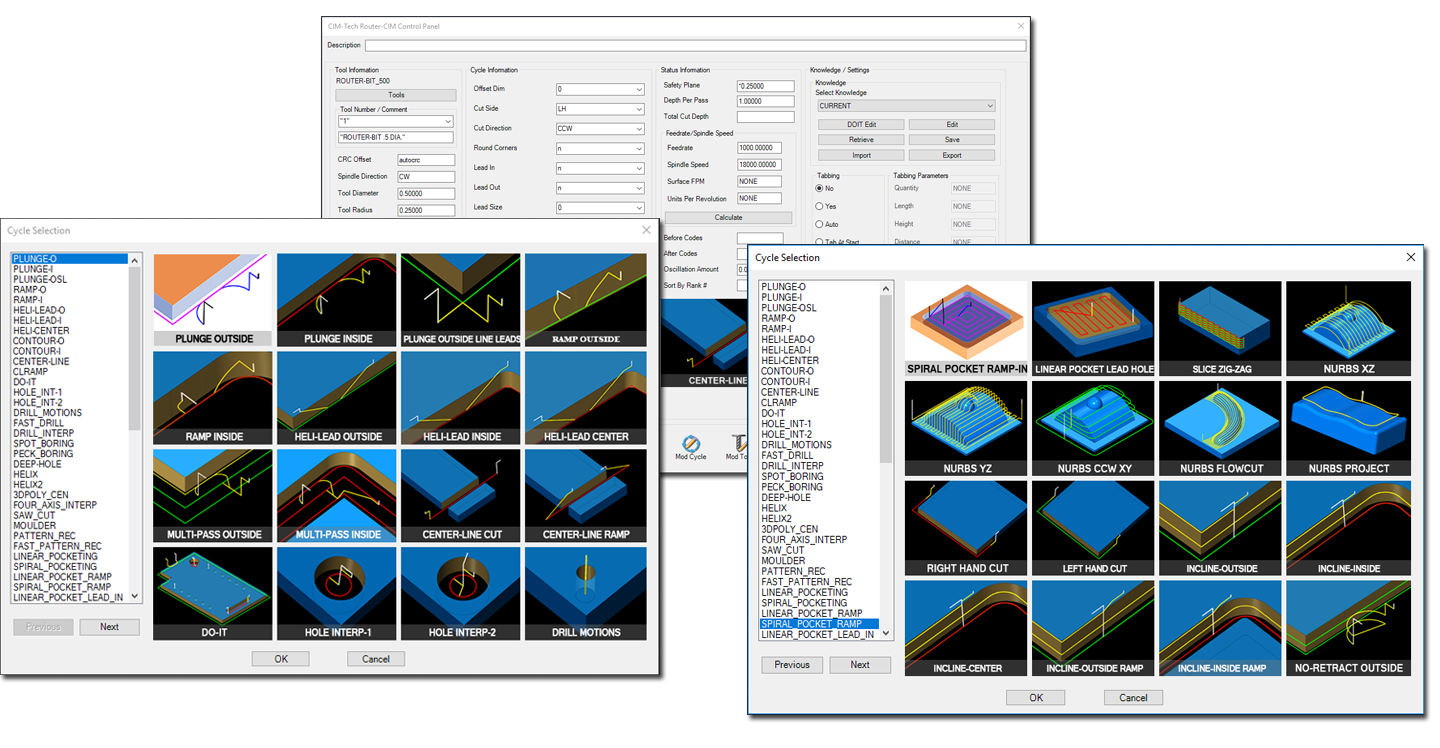

The main interface screen has a familiar Windows style, which allows jobs and parts to be selected from a tree-style interface. Our all-in-one screen for tool path parameters is easy to learn and use. We've organized all of the machining parameters into one easy-to-use interface.

This screen is set up and saved as "Knowledge".

This information is easily archived, and can be transferred from one computer to another.

Competitive software packages charge over $5000 for this option (if they even have it); we include it at no additional charge and can even automate the cutting process with layer to knowledge!

Includes bar-coded and bitmapped labeling: Our labeling utilizes the latest Avery software (included) and works with any printer. Out labels are fully customizable and we have 10 user definable label fields that can be imported from spread sheet or CSV files. We also make a laser projection .dxf file to support overhead laser part projection

Established in 1986, the founders of CIM-TECH realized that a CNC machine was only as good as your ability to program it. Computer Integrated Manufacturing (CIM) was needed to bridge the gap between Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM). CIM provides for a seamless solution with a common interface for design and manufacturing. From this basic concept a new company was created, CIM-TECH.

Read more7512 Dr. Phillips Boulevard Suite 50-859, Orlando, FL 32819

Telephone: 877-549-8211

E-mail: info@cim-tech.com